In recent years, 3D printing technology has revolutionized various industries, from manufacturing to healthcare, architecture, and beyond. As we enter 2025, this technology continues to evolve at a rapid pace, bringing new possibilities and pushing the boundaries of what was once thought possible. In this blog, we will explore the top 10 innovations in 3D printing technology for 2025, highlighting the advancements that are shaping the future of design, production, and creativity.

Top 10 Innovations in 3D Printing Technology

Here are the top 10 breakthroughs that are shaping the future of 3D printing and transforming various industries

3D Printing with Sustainable Materials:

As sustainability becomes a growing concern, the demand for eco-friendly solutions is rising. In 2025, one of the most significant innovations in 3D printing is the use of sustainable materials. Companies are now developing filaments made from recycled plastics, plant-based polymers, and biodegradable materials. These innovations are not only reducing waste but also making 3D printing more environmentally responsible. 3D printing with sustainable materials is set to revolutionize industries like packaging, construction, and fashion.

Metal 3D Printing Advancements:

Metal 3D printing technology has come a long way since its inception, and in 2025, it’s even more sophisticated. Innovations in metal 3D printing now allow for the production of highly complex and durable metal parts, used in industries like aerospace, automotive, and healthcare. New techniques, such as direct energy deposition (DED) and selective laser melting (SLM), are enabling more precise and efficient manufacturing of metal components, including functional prototypes and end-use parts.

Multi-Material 3D Printing:

In 2025, multi-material 3D printing is making it easier to combine various materials in a single print, offering even more flexibility in design and function. This advancement allows for the production of objects with multiple properties, such as soft and rigid materials or different colors and textures. Multi-material 3D printing is particularly useful in applications like robotics, automotive manufacturing, and healthcare, where different material properties are required for different parts of a product.

AI-Powered 3D Printing:

Artificial intelligence (AI) is transforming many industries, and AI-powered 3D printing is one of the most exciting developments in 2025. AI algorithms are now being integrated into 3D printers to optimize the design process, improve print quality, and reduce material waste. AI can predict print failures before they happen and make real-time adjustments to ensure optimal results. This AI-driven innovation is helping engineers and designers create faster, smarter, and more efficient prints.

3D Printing in Healthcare: Bioprinting Advancements:

3D printing in healthcare has seen incredible advancements in recent years, and 2025 is no different. One of the most promising innovations is bioprinting, which involves printing with living cells to create tissues and organs. In 2025, bioprinting technology is becoming more advanced, enabling the creation of complex, functional tissues that can be used for medical research, drug testing, and eventually, organ transplantation. This breakthrough has the potential to save millions of lives and reduce the need for organ donors.

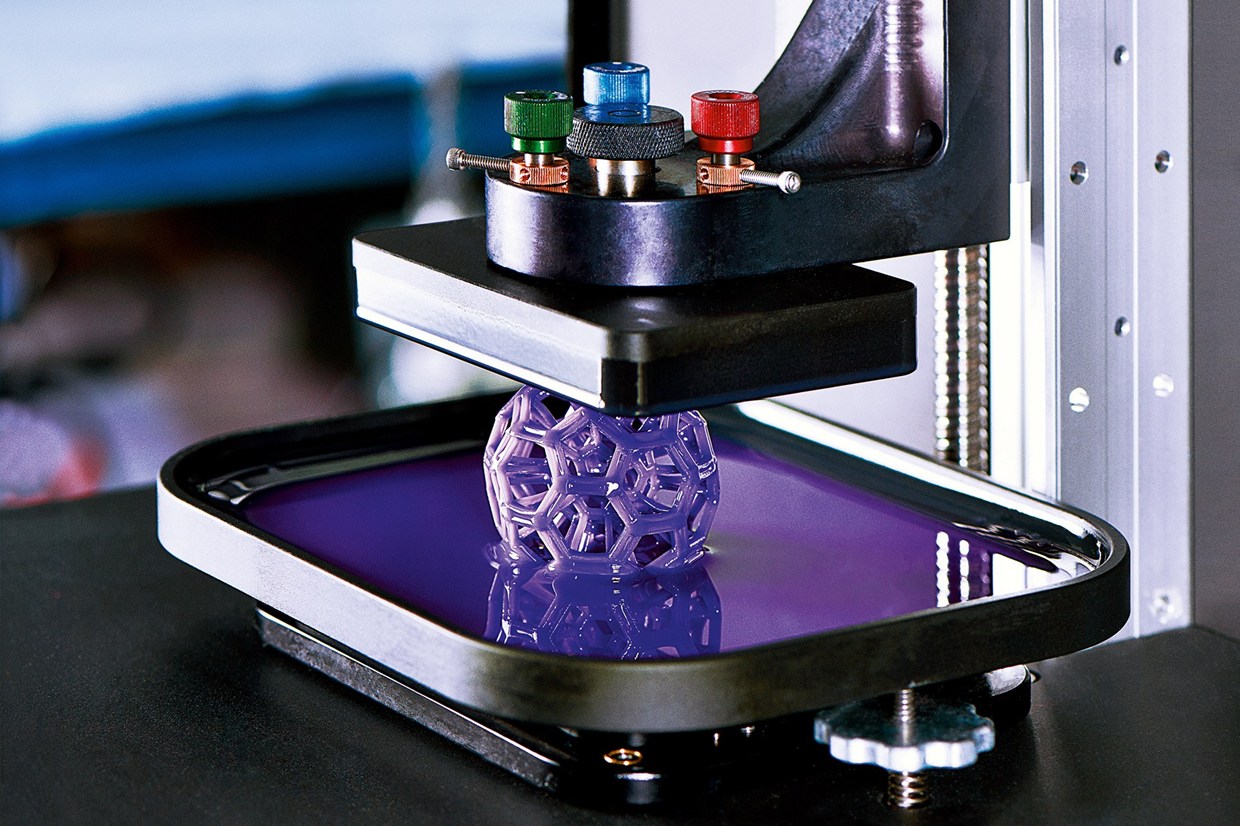

Faster 3D Printing with Continuous Liquid Interface Production (CLIP)

CLIP technology has taken 3D printing to the next level by enabling the continuous production of high-quality 3D printed objects. Unlike traditional 3D printing, which builds objects layer by layer, CLIP uses light and oxygen to cure resin in a continuous process. This innovation in 3D printing drastically reduces the printing time, allowing for faster production of prototypes and end-use products. CLIP is being widely adopted in industries such as automotive, aerospace, and consumer products.

3D Printing in Construction

In 2025, the construction industry is embracing 3D printing technology to create more affordable and sustainable housing. 3D-printed homes are becoming a reality, with large-scale 3D printers capable of printing entire structures using concrete and other construction materials. These innovations are reducing construction time and costs while also enabling more personalized, sustainable designs. 3D printing in construction is paving the way for the future of urban development and architecture.

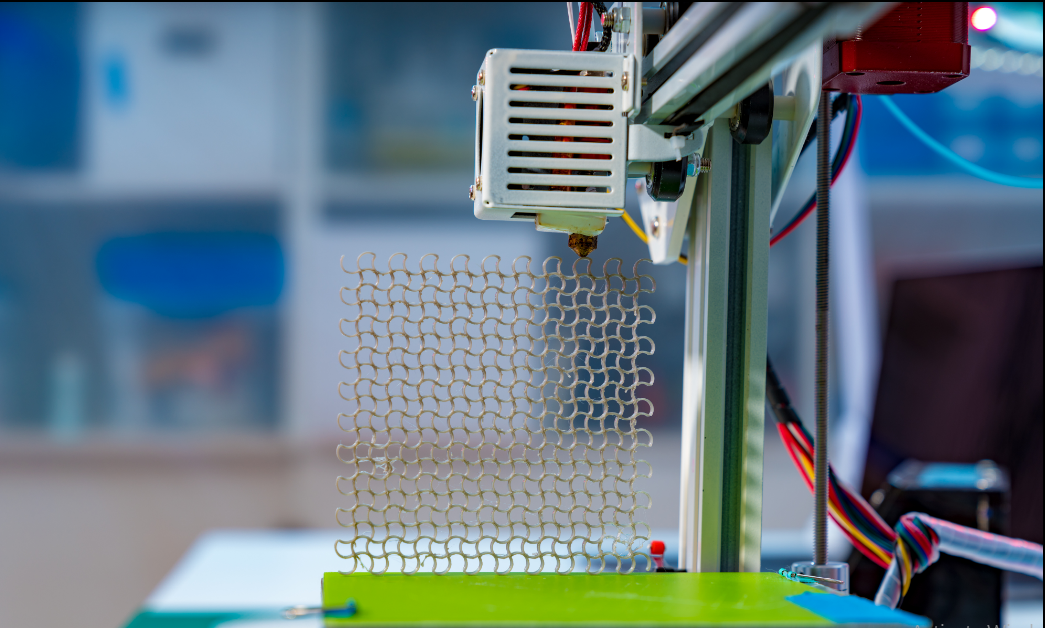

Customization with 3D Printed Fashion

The fashion industry is also embracing 3D printing technology for the creation of custom clothing and accessories. 3D printed fashion allows designers to create unique, intricate designs that would be impossible to achieve with traditional manufacturing methods. In 2025, we’re seeing even more innovations in 3D-printed fashion, with designers experimenting with new materials, such as flexible filaments and textiles, to create wearable art. This innovation offers endless possibilities for personalized, one-of-a-kind fashion pieces.

3D Printing for Food Production

3D printing in food production is one of the most unconventional but exciting innovations. In 2025, 3D printers are being used to create customized, nutritious, and delicious food items. Whether it’s printing chocolate, pizza, or even more complex dishes, 3D printing technology is revolutionizing the food industry by enabling on-demand, precision cooking. 3D printed food has the potential to reduce food waste, create healthier meals, and provide solutions for global food shortages.

Cloud-Based 3D Printing

Cloud computing is increasingly integrated with 3D printing technology to allow users to design, store, and manage 3D models remotely. Cloud-based 3D printing enables collaboration between designers, engineers, and manufacturers from different locations, streamlining the production process. In 2025, cloud-based platforms are becoming more sophisticated, offering features like real-time tracking, remote printing, and enhanced security. This technology is making 3D printing more accessible to individuals and companies across various industries.

FAQs

Top Innovations in 3D Printing Technology for 2025?

In 2025, 3D printing will advance with sustainable materials, metal printing, bioprinting, AI optimization, and faster processes like CLIP. Innovations will reshape construction, fashion, and food industries, offering eco-friendly, custom solutions for enhanced design and production efficiency.

What is metal 3D printing, and which industries benefit from it?

Metal 3D printing produces complex and durable parts using advanced techniques like selective laser melting (SLM). Industries such as aerospace, automotive, and manufacturing rely on metal 3D printing for prototypes and end-use parts.

What are the benefits of AI-powered 3D printing?

AI-powered 3D printing enhances the design process, improves print quality, reduces material waste, and predicts failures to ensure efficient and optimized production.

What are the career benefits of completing a 3D Printing Training & Certification Course?

A 3D printing course at CADD Centre provides globally recognized certification, hands-on training, and placement support. Gain industry-relevant skills and explore opportunities as a 3D Printing Specialist in fields like manufacturing and healthcare. Stay ahead with insights into trends like bioprinting and unlock global career growth

What is the projected global 3D printing market value in 2025?

The global 3D printing market is forecasted to reach USD 23.41–29.29 billion in 2025, depending on different research sources. This marks a strong year-on-year growth from 2024, supported by wider adoption in manufacturing, healthcare, construction, and consumer products.

How fast is the 3D printing service segment growing through 2029?

The 3D printing services market—covering areas like prototyping, on-demand production, and cloud-based design—is growing at a CAGR of 21.7%. It is expected to expand from USD 8.95 billion in 2025 to USD 16.28 billion by 2029, driven by businesses outsourcing 3D printing instead of investing in full in-house setups.