Introduction:

In today’s fast-paced industrial environment, damaged or broken parts can halt production, leading to significant downtime and costly delays. Whether due to obsolescence or the high expense of replacements, reverse engineering emerges as a critical solution. Reverse engineering is the systematic process of analyzing, replicating, and improving existing products. This blog explores the various applications and benefits of reverse engineering, particularly in the recovery of broken parts.

Understanding Reverse Engineering:

What is Reverse Engineering?

At its core, reverse engineering involves the dissection of a product to understand its design, materials, and functionality. This process is crucial not only for restoring damaged parts but also for improving existing designs and creating accurate digital models. With the help of advanced tools like 3D scanning and CAD software, reverse engineering provides immediate feedback and higher accuracy, making it an indispensable tool in modern manufacturing.

Key Applications of Reverse Engineering

1. Restoring Damaged or Obsolete Parts

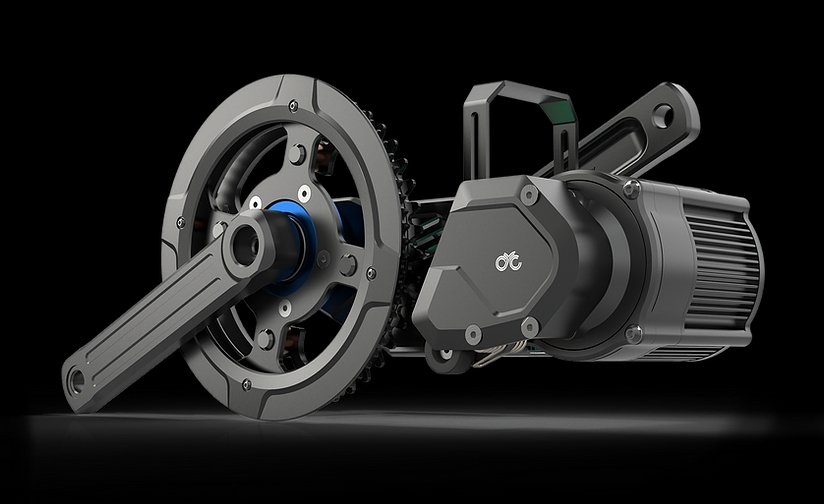

One of the primary applications of reverse engineering is the recovery of parts that are either damaged beyond repair or no longer in production. This process allows manufacturers to recreate parts with precision, ensuring that machinery continues to function without interruption. High-precision CAD models generated through reverse engineering enable seamless reproduction of even the most complex components.

2. Design Optimization and Product Improvement

Reverse engineering isn’t just about replication; it’s also a powerful tool for innovation. By analyzing and re-engineering existing products, companies can optimize designs, improve performance, and reduce costs. This approach is particularly valuable in industries such as automotive, aerospace, and medical devices, where precision and efficiency are paramount.

3. Reverse Engineering in Historical Preservation

Beyond industrial applications, reverse engineering plays a crucial role in the preservation and restoration of historical artifacts. Museums and archaeologists use this technology to replicate ancient tools, sculptures, and other artifacts, ensuring their longevity for future generations.

The Reverse Engineering Process: From Scanning to Solid Modeling

1. The Scanning Phase

The reverse engineering process begins with the scanning phase, where the physical object is digitally captured using 3D scanning technologies. This step is essential for creating an accurate representation of the part’s geometry, material properties, and surface quality.

2. Point Cloud Processing

Once the scan is complete, the data is processed to generate a point cloud, which serves as the foundation for the digital model. This phase involves cleaning and refining the data to remove any noise or errors.

3. Solid Modeling and CAD Integration

The final step in reverse engineering is converting the point cloud into a solid model using CAD software. This model can then be used for various purposes, including manufacturing, simulation, and further design modifications.

Future of Reverse Engineering: AI and Machine Learning Integration

The future of reverse engineering lies in the integration of artificial intelligence (AI) and machine learning. These technologies have the potential to automate the reverse engineering process, reducing time and improving accuracy. As AI continues to evolve, we can expect reverse engineering to become even more efficient and widely adopted across various industries.

Conclusion:

Reverse engineering is vital for restoring damaged parts, optimizing designs, and preserving historical artifacts. As technology advances, its applications will continue to grow, making it crucial for industries worldwide.

For those seeking expertise in reverse engineering, CADD Centre offers top-notch training programs. With CADD Centre, you’ll gain the skills needed to harness the power of reverse engineering and stay competitive in today’s market.

FAQs

What is reverse engineering, and how does it help in recovering broken parts?

Reverse engineering involves analyzing and replicating an existing product to understand its design and functionality. It helps in recovering broken parts by allowing manufacturers to recreate precise replicas, even for obsolete or damaged components, ensuring machinery continues to operate without interruption.

What technologies are used in the reverse engineering process?

Reverse engineering utilizes advanced technologies like 3D scanning, point cloud processing, and CAD software. These tools help create accurate digital models of the original parts, which can then be used for reproduction or further design modifications.

How does CADD Centre ensure the quality and accuracy of its reverse engineering training?

CADD Centre ensures high-quality and accurate training by using industry-standard tools, real-world case studies, and hands-on projects. Our experienced instructors provide practical insights and guidance to help students master reverse engineering techniques effectively.

What are the challenges of reverse engineering?

Challenges in reverse engineering include accurately capturing damaged or complex parts, ensuring precision in 3D scanning, and handling legal issues related to intellectual property. The process can be time-consuming and requires skilled use of CAD software.

What industries benefit the most from reverse engineering?

Industries like automotive, aerospace, and medical devices benefit greatly from reverse engineering, as it helps in replicating obsolete parts, optimizing designs, and maintaining essential equipment. It’s also valuable in historical preservation for restoring artifacts.