Manufacturing engineers are a set of highly technical people who play a major role in product processing, engineering, and manufacturing processes. The Manufacturing Engineers work to plan, design, set, modify, optimize, and monitor the manufacturing processes.

As Manufacturing Engineer’s job profiles are similar across industries, they work over various engineering and manufacturing industries and numerous sectors such as Food and Drinks, Biotechnology, Oil, Plastics, Pharmaceuticals, etc. These professionals work to offer high-quality goods efficiently using the most cost-effective methods and with the aim to reduce the harmful impact of production on the environment.

Skills Manufacturing Engineers must Possess

1. The ability to understand a variety of engineering operations and procedures

2. Practical and logical approach towards problem-solving

3. People management skills and teamwork.

4. Time Management and Organizational Skills.

Job Responsibilities

The key responsibility of a Manufacturing Engineer lies in the engineering and manufacturing process of products. Some of them are:

- Designing new systems to introduce new products or improving the existing ones.

- Working with other team members such as mechanical, chemical, and electrical to ensure all product requirements are taken into account.

- Supervising junior engineers and contractors for effective communication to avoid errors.

- To ensure best practices are adopted in developing and delivering products

Job Opportunities and Salaries

As Engineering and Manufacturing practices are needed in almost every industry from food to plastics, there is a huge demand for Manufacturing Engineers in the market. Being highly qualified and efficient in their undertakings, these are the professionals that earn up to $78,000.

Challenges Faced by Manufacturing Engineers

Manufacturing engineers encounter several challenges, including:

- Process Optimization: Continuously improving manufacturing processes to meet changing demands and standards.

- Resource Management: Efficiently managing materials, time, and labor to maximize productivity and minimize waste.

- Technology Integration: Adapting to new technologies and integrating them into existing systems can be complex and requires ongoing learning.

Conclusion:

The CADD Centre for Technical Training and Education offers courses that make engineering candidates skilled through their programs. Programs such as NX CAM offers a complete solution for part manufacturing and tooling design software taking care of all engineering and manufacturing needs. NX CAD training is another solution that makes candidates skilled in Design, Simulation, and Manufacturing processes. The highly skilled training group offers standard as well as customized training programs for aspiring engineering candidates making them competent for the market needs.

FAQs

Tools and Software for Manufacturing Engineers?

Key tools and software used by manufacturing engineers include:

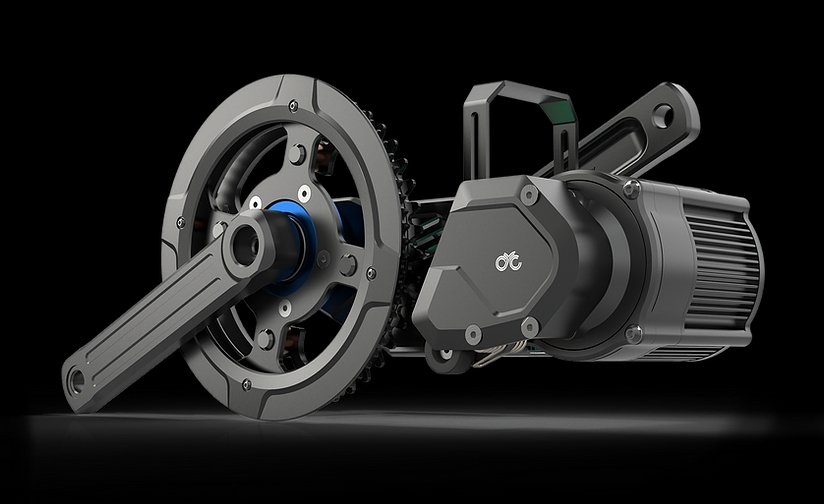

- NX CAM: Provides solutions for part manufacturing and tooling design, streamlining the production process.

- NX CAD: Offers capabilities for design, simulation, and manufacturing, helping engineers create and refine product designs.

What industries employ manufacturing engineers?

Manufacturing engineers work across a variety of industries, including food and drink, biotechnology, oil and plastics, pharmaceuticals, and more. Their skills are applicable to many sectors where products are designed and produced.

What educational background is required to become a manufacturing engineer?

A degree in mechanical, industrial, or manufacturing engineering is typically required. Additional certifications and continuous learning are also beneficial for career advancement.

What technologies are important in modern manufacturing engineering?

Important technologies include automation and robotics, Computer-Aided Design (CAD) software, and Industry 4.0 technologies. These innovations enhance efficiency, precision, and data-driven decision-making in manufacturing processes.

How can CADD Centre’s programs help aspiring manufacturing engineers?

CADD Centre offers specialized programs like NX CAM and NX CAD that provide training in part manufacturing, tooling design, and other key areas. These programs equip candidates with the skills needed to excel in manufacturing engineering