Formula 1 victories are often attributed to outright speed, driver skill, or strategic brilliance on race day. In practice, championships are rarely decided on Sunday afternoons alone. They are the result of months of disciplined engineering decisions made far from the circuit.

At the centre of modern motorsport engineering lies digital product design, where performance is defined long before a car turns its first lap. For McLaren, one of Formula 1’s most technically rigorous teams, this process is built around CATIA software—a platform that enables engineers to design, validate, and refine every component of a championship-winning car in a fully digital environment.

In an era where regulations are tight and margins are microscopic, CATIA has become less a design tool and more an engineering backbone.

Design Comes Before the Podium:

Before a McLaren Formula 1 car ever reaches the grid, it exists entirely as data.

Using CAD software for engineering, McLaren engineers develop highly detailed digital representations of the car, resolving geometry, interfaces, tolerances, and assemblies well in advance of manufacturing. Through CATIA mechanical design, each subsystem—from suspension components to aerodynamic structures—is modelled with precision, ensuring compatibility across the entire vehicle architecture.

These detailed 3D models are not static drawings. They are living digital products that evolve continuously as regulations change, performance targets shift, and new insights emerge. In Formula 1 car design, this digital-first approach is not optional—it is a necessity.

The podium, in many ways, is only the final confirmation of decisions already made in the design phase.

Advanced Surface Modeling: The Aerodynamic Advantage

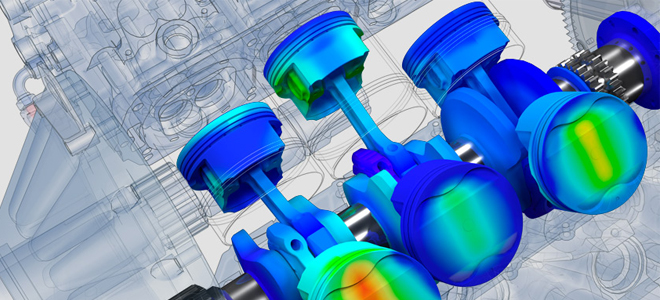

Aerodynamic performance in Formula 1 is rarely obvious to the naked eye. It emerges from thousands of subtle decisions in surface geometry, each influencing how air flows across, under, and through the car.

Through advanced surface modeling in CATIA, engineers gain fine control over curvature continuity, edge conditions, and surface transitions. These surfacing tools allow McLaren to sculpt aerodynamic forms that optimise airflow behaviour while remaining manufacturable and compliant with regulations.

As an aerodynamic design software, CATIA plays a critical role in translating aerodynamic intent into precise geometric definition. Minor changes in surface curvature can mean the difference between stable downforce and disruptive turbulence. In this environment, geometry is not aesthetic—it is functional, constrained, and unforgiving.

Managing Complexity with Parametric Design:

A Formula 1 car is one of the most complex mechanical systems ever built. It operates under extreme regulatory, spatial, and temporal constraints, with thousands of interdependent components working as a single system.

This is where parametric design becomes essential. Using engineering design software like CATIA, McLaren engineers establish intelligent relationships between components, allowing design changes to propagate systematically across the entire model.

With assembly design in CATIA, the car is structured into coordinated sub-assemblies, ensuring that modifications in one area whether driven by performance, regulation, or manufacturing do not destabilise the overall architecture. Instead of simplifying complexity, CATIA enables teams to manage it with control and clarity.

Why CATIA Is the Preferred Software in Formula 1 & Automotive Engineering?

Formula 1 teams do not select tools lightly. The demands of modern motorsport require software that can handle extreme complexity without compromising accuracy or speed.

Among the most critical CATIA software uses are high-order surface control, large-scale assembly management, and end-to-end design continuity. Through CATIA parametric modeling, teams can iterate rapidly while preserving design intent and system integrity.

Beyond Formula 1, CATIA applications are widespread across the automotive industry, where similar challenges exist: tight packaging, regulatory pressure, and the need for seamless collaboration between design, analysis, and manufacturing teams.

CATIA’s strength lies not just in modelling capability, but in its ability to act as a single source of engineering truth.

These Skills Go Beyond Motorsport

While Formula 1 offers a dramatic illustration of CATIA’s capabilities, the same principles apply across multiple industries.

In automotive development, automotive design software like CATIA is used to engineer production vehicles, electric platforms, and advanced mobility systems. For individuals pursuing product design careers, the skills developed through CATIA—systems thinking, parametric control, and surface precision—are directly transferable.

Similarly, in industrial design engineering, CATIA supports the development of complex products ranging from heavy machinery to consumer goods, where performance, manufacturability, and lifecycle considerations must be balanced. Motorsport simply reveals these demands in their most concentrated form.

Learning CATIA for Industry-Ready Careers:

As industries increasingly adopt digital-first workflows, formal training in CATIA has become a strategic advantage.

A structured CATIA course introduces learners to professional-grade 3D design software, covering everything from surface and solid modelling to assemblies and design intent management. Mastery of solid modeling techniques enables engineers to translate conceptual ideas into production-ready designs with confidence.

For aspiring professionals, learning CATIA is not about mastering software for its own sake, it is about understanding how modern engineering problems are solved in real-world environments.

Conclusion:

McLaren’s championship-winning Formula 1 cars illustrate a broader truth about contemporary engineering. Performance today is not discovered through experimentation alone,it is engineered through disciplined, digital-first design processes.

For mechanical design engineers and product designers, CATIA represents more than a modelling tool. Whether applied in motorsport, automotive development, or industrial engineering, CATIA software enables professionals to manage complexity, preserve design intent, and translate ideas into manufacturing-ready systems.

FFor those seeking to build these capabilities, structured learning matters. At CADD Centre, programmes such as Essentials in CATIA with AI introduce the foundations of modern 3D design and parametric thinking, while Proficient in CATIA with AI advances learners toward industry-level application, integrating intelligent workflows, system-level design, and real-world engineering scenarios.

As industries increasingly converge around digital product development, product design careers will favour those who understand how world-class engineering is designed, long before it is built.

FAQs

1. Which parts of a Formula 1 car are designed using CATIA?

Most components, including aerodynamic surfaces, suspension systems, chassis elements, and assemblies, are designed and integrated using CATIA.

2. Why do Formula 1 teams prefer CATIA over other CAD software?

Teams value CATIA for its advanced surface modelling, parametric design capabilities, large assembly handling, and seamless design-to-manufacturing workflows.

3. Is CATIA used only in Formula 1 motorsport?

No. CATIA is widely used in automotive, aerospace, industrial design, and manufacturing industries.

4. Which CATIA courses offer industry-recognized certification?

Industry-recognized CATIA certifications are offered through authorised training centres with structured, industry-aligned curricula.

At CADD Centre, learners can choose from the following certification-focused programmes:

- Essentials in CATIA with AI – Builds strong foundational skills in CATIA while introducing AI-assisted design workflows.

- Proficient in CATIA with AI – An advanced programme focused on complex surface modeling, parametric design, and AI-enabled product design practices.

Both courses are designed to prepare learners for real-world product design roles across automotive, aerospace, and advanced manufacturing sectors.

5. What industries use CATIA besides motorsport?

CATIA is used across automotive, aerospace, industrial machinery, consumer product design, and advanced manufacturing sectors.