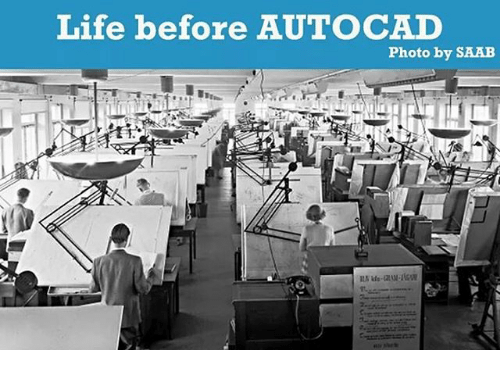

In various industries, ranging from aerospace to power generation, challenges arose due to the complications posed by parts and equipments crafted during the pre-CAD era. Things that were designed without the benefit of CAD technology used to lack the critical documentation and information that was necessary for creating accurate models. Therefore, the necessity for reverse engineering emerged, enabling the generation of CAD models essential for engineers, thereby coming into existence.

Understanding Reverse Engineering

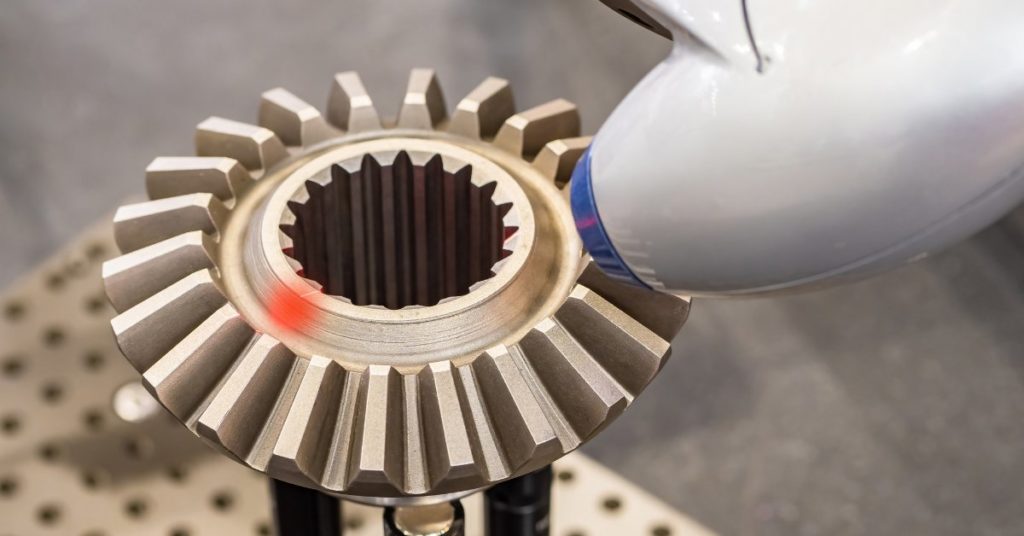

Reverse engineering is a technology that helped in creating a three-dimensional virtual model of an existing physical part. Manufacturers used reverse engineering to deconstruct products or systems, assessing, enhancing, or reshaping outdated design information for further advancement. However, now there are a number of optical measurement systems available for engineers today that are the best alternative to previous methods. Have a look at the tools that are now mainly used for reverse engineering:

Handheld Scanner

Traditional methods such as creating 3D models based on hand measurement and 2D drawing are expensive and time-consuming. Therefore, it became crucial to use 3D scanning for reverse engineering. . Handheld scanners excel in digitizing 3-D surfaces and seamlessly transferring relevant information into CAD systems. Renowned for expediting the reverse engineering process, these tools are particularly acclaimed.

CAD Design with SolidWorks

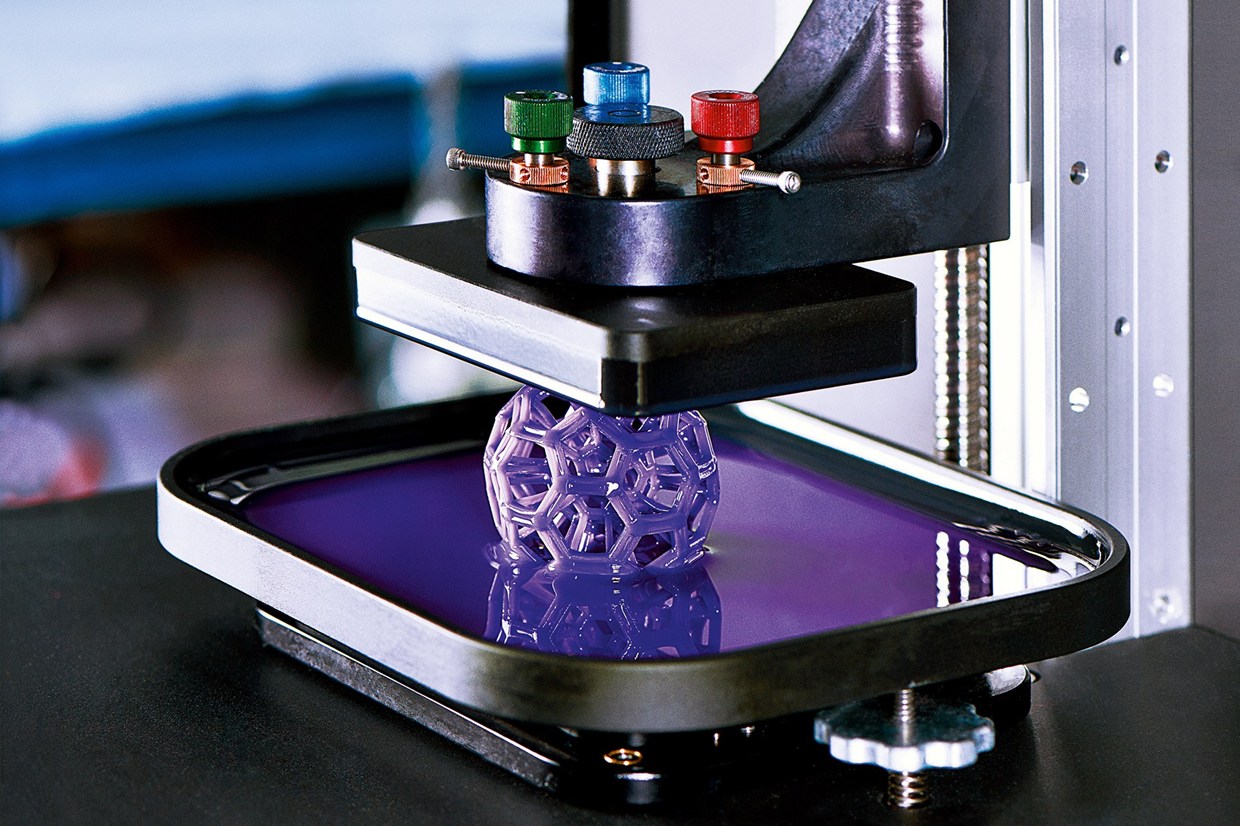

Solidworks stands out as the globally preferred tool, facilitating the streamlining of the design process through the enhancement of existing designs or the creation of new ones. It can help in the development of 3D models, export to the 3D printer for the development of a prototype, or create molds.

Point Cloud

3D scanners generate Point Clouds by capturing extensive data points across the surface of an object, presenting the output in a data file format. Therefore, the point cloud is used in the development of 3D CAD models, particularly in quality inspection, animation, visualization, and the manufacturing of parts.

Geomagic Design X

The tool is built for converting 3D scan data to high-quality and feature-oriented CAD models. Geomagic Design X not only helps in creating feature-based models but also an editable solid model that is compatible with the existing CAD software. Additionally, it stands out as the most comprehensive reverse engineering software available.

HighRES Add-in for Inventor

This highly compatible laser scanning software excels in effortlessly transferring scanned data, paving the way for further enhancement and utilization. The tool can help in obtaining measurement data, convert it to a parametric CAD model, and has many more features. They are developed in order to support the current release of the respective CAD/CAM software.

Innovation for the Future

The mentioned software comprises a list dedicated to active development, placing a strong emphasis on renewal and innovation. If you are seeking a reliable partner to assist you in navigating the realm of reverse engineering tools in CAD Modeling, consider enrolling in the Product Design using Reverse Engineering course offered by CADD Centre. Within the course, professionals with expertise in reverse engineering will help in your knowledge expansion and subject training.

FAQs

Q: What are the primary specifications covered in CAD Modeling courses provided by CADD Centre?

The courses cover a comprehensive range of specifications, including 2D drafting, 3D modeling, assembly design, parametric design, rendering, and visualization. In autocad mechanical course students also learn industry standards, best practices, and project-based applications.

Q: What are some popular reverse engineering tools used in CAD modeling?

Several tools are widely used for reverse engineering in CAD modeling, including:

- 3D scanning devices (e.g., laser scanners, structured light scanners)

- CAD software with reverse engineering capabilities (e.g., Autodesk ReCap, Geomagic Design X)

- Point cloud processing software (e.g., CloudCompare, PolyWorks)