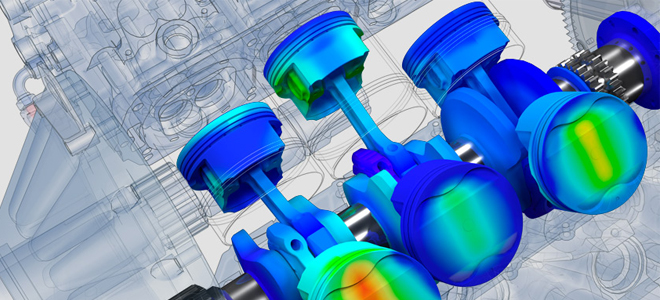

Welcome to the cutting edge: Simulation-Driven Product Development is not just a buzzword—it’s becoming the industry standard. As 2025 unfolds, we’re seeing pioneering trends that are reshaping how products are designed, validated, and brought to market faster, smarter, and more efficiently. In this post, we’ll explore real-time, data-backed developments driving the future of simulation-driven engineering, backed by industry insights and compelling stats.

1) AI-Powered Acceleration of Simulation:

Artificial intelligence is transforming traditional simulation by enhancing speed, accuracy, and adaptability. Platforms like Altair’s HyperWorks® use AI-enabled tools such as PhysicsAI™, delivering simulation outcomes up to 1,000× faster than conventional solvers. This leap opens doors to rapid iteration and empowers engineers for innovation without compromise.

2) Digital Twins: High-Fidelity & Real-Time Modeling

High-fidelity digital twins are increasingly pivotal in mimicking real-world behavior with precision. As per forecasts, the high-fidelity digital twin simulation market is expanding rapidly, propelled by AI-driven modeling, cloud-native platforms, and edge computing. Additionally, over 75% of firms engaging with IoT are already deploying or planning to use digital twins soon.

3) Immersive Interactions via AR, VR & Industrial Metaverse:

Immersion is the new interface. AR and VR integration with digital twins creates intuitive, 3D interaction models that elevate virtual inspections, design reviews, and collaborative workflows. Notably, industrial metaverse platforms—like BMW’s use of NVIDIA’s Omniverse—enable “virtual factories” that streamline planning and eliminate costly errors before physical construction begins.

4) IoT, Edge Computing & Sensor Fusion Driving Real-Time Simulations:

Connected devices are at the core of modern simulation. IoT sensors and edge computing empower real-time data ingestion and low-latency processing, making simulations more responsive and scalable. Whether it’s monitoring smart equipment or adjusting industrial processes on the fly, this trend is fundamental to simulation’s future.

5) Adaptive & Self-Updating Digital Twins with LLMs:

Emerging techniques like Large Language Models (LLMs) are enabling digital twins that learn and self-update dynamically. For example, CALM-DT frameworks adapt to evolving environments through in-context learning, eliminating static models and enabling continuous alignment with real-world changes

6) Integrated AI Simulation for Optimization & Decision-making:

Simulation is no longer siloed—it’s integrated into the AI-driven decision chain. Hybrid models combining domain knowledge, AI, and physics-based constraints are enabling robust, interpretable simulation-heavy design strategies. Digital twins also play a vital role as virtual training grounds for AI, improving algorithms in a risk-free environment.

7) Scalability & Interoperability via Cloud & Standards:

Simulation platforms are becoming more scalable and connected thanks to cloud-native architectures and open standards. Such infrastructure allows seamless integration between simulations, enterprise systems, and IoT ecosystems—fostering cross-industry collaboration.

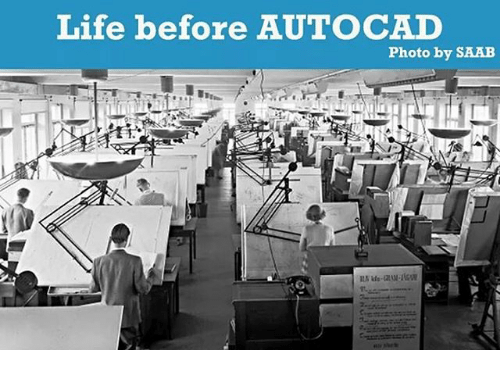

8) Simulation-First Workflows (“Shift-Left” Design):

Forward-thinking engineering organizations are embracing simulation early in the development lifecycle. This “shift-left” methodology—often referred to as simulation-driven design—enables rapid iteration, reduced prototyping costs, and smarter decision-making from the outset.

9) Sustainability Through Simulation & Digital Twins:

Environmental stewardship is driving simulation’s expanded role in sustainability. Digital twins help enterprises evaluate carbon footprint, energy optimization, and resource management, aligning product development with net-zero goals.

10) Market Expansion & Business Value Amplification:

From $35B in 2024 to projections of $379B by 2034, the simulation and digital twin market is exploding in value. This reflects how simulation is no longer niche—it’s a strategic asset fueling business transformation.

Conclusion:

The future of simulation-driven product development in 2025 is set to revolutionize industries with digital twins, AI-driven insights, and cloud-powered collaboration. As companies embrace these trends, skilled professionals will be in high demand. Upskilling through an ANSYS Certification Course at CADD Centre can prepare engineers and designers to lead this transformation, ensuring they stay ahead in the evolving world of product development.

FAQs:

How simulation-driven design reduces product development costs

Simulation-driven product development has enabled companies in aerospace, automotive, and healthcare to shorten design cycles, improve product reliability, and launch innovative products faster than competitors.

Why does early design validation save time and money?

By validating designs early through simulation, engineers can detect flaws before production, reducing costly rework, minimizing delays, and ensuring smoother product launches.

How does simulation-driven design reduce product development costs?

By replacing multiple physical prototypes with virtual simulations, companies cut material expenses, testing costs, and labor hours. This makes the development process more efficient and cost-effective.

How are ANSYS tools used in simulation-driven product development?

ANSYS tools provide advanced simulation capabilities such as structural analysis, thermal modeling, and fluid dynamics. These features help engineers optimize performance, improve efficiency, and innovate confidently.

How can I start a career in simulation-driven product development?

Pursuing an ANSYS Certification Course at CADD Centre equips learners with the technical expertise and practical skills required to excel in simulation-driven design and secure high-growth opportunities in engineering.