Introduction

An RCC box culvert is a rigid cross drainage structure constructed using a reinforced concrete culvert system that enables water flow beneath highway or railway embankments. In modern rcc box culvert design, the structural response is influenced not only by self-weight and earth pressure, but also by moving vehicular loads that introduce dynamic stress variations and complex internal force patterns. As considered in box culvert design as per IRC, traffic loading plays a critical role in defining the internal force envelope and overall safety requirements.

At first glance, the structural system may appear to behave like a simple slab resting under soil cover. However, once traffic begins to move above it, the structural performance of box culverts becomes more intricate. Subtle variations in cushion depth, axle configuration, and load intensity can significantly alter bending moments, shear forces, and stress redistribution. In the sections ahead, we will examine how these parameters interact within the culvert system and reveal why live loads often govern key design decisions under real service conditions.

Understanding Live Loads in Culvert Design

Live loads arise due to vehicular movement over the culvert. The live load distribution in culverts depends on axle configuration, pavement layers, and fill depth. Standard loading systems such as IRC Class A loading, IRC 70R loading, and AASHTO HL-93 loading define the magnitude and arrangement of traffic loads for design purposes.

The vehicular load on culvert produces vertical reactions and dynamic amplification accounted for using the impact factor in culvert design. In certain cases, longitudinal effects comparable to braking forces in bridges may also be considered. These loads govern internal force development within the culvert slabs and walls.

Load Dispersion Mechanism

When a vehicle wheel applies load on the pavement surface, the force undergoes wheel load dispersion as it travels downward through the pavement layers and embankment. This process increases the contact area before the load reaches the top slab. The effectiveness of this spread depends on fill height, soil stiffness, and compaction quality.

As the stress moves deeper, it undergoes load dispersion through soil, reducing intensity but widening its influence zone. This gradual spreading modifies how the slab experiences pressure and directly affects bending and shear demand within the structural frame.

The interaction between soil and structure is governed by the load transfer mechanism, which explains how vertical stress transitions from the soil mass to the concrete slab. Engineers commonly evaluate this behavior using the effective width method, where the slab width contributing to resistance is estimated based on dispersion assumptions and codal guidelines.

Through this approach, designers can determine the resulting soil pressure distribution acting on the slab surface. A shallow cushion typically results in concentrated stress patterns, while greater fill depth promotes wider distribution and smoother stress gradients. However, improved dispersion in the slab may influence reaction forces along the walls, altering the overall internal force balance of the culvert.

Soil-Structure Interaction

The behavior of a culvert is significantly influenced by soil structure interaction in culverts. The presence of earth fill above culvert modifies how loads are transmitted. The cushion depth in box culvert plays a decisive role in determining stress levels.

The difference between culvert with and without cushion is considerable. With shallow fill, live loads act almost directly on the slab, producing higher bending effects. As fill depth increases, dispersion improves and slab demand reduces, although lateral soil pressure on walls increases. Understanding how fill depth affects live load on culverts is essential for achieving balanced structural performance.

Impact on Structural Performance

Live loads significantly influence the bending moment in box culvert, shear force in culvert slab, and top slab moment variation under critical load combinations. Under heavy loading such as IRC 70R loading, internal forces can increase substantially.

Improper assessment may result in culvert cracking due to overload or excessive deflection observed during culvert deflection analysis. These responses directly affect the structural stability of culverts and long-term durability.

Digital Validation & Software Analysis

Advanced analytical tools enhance design reliability. Engineers commonly use STAAD Pro culvert analysis, finite element analysis of culvert, and detailed FEA for box culvert modeling to simulate realistic load behavior. Proper load combination in STAAD Pro ensures that critical scenarios are evaluated accurately. Techniques such as bridge deck modeling in STAAD further improve representation of load application.

Such digital validation supports compliance with a structured rcc box culvert design guide and established culvert design standards in India.

Practical Case Study Example

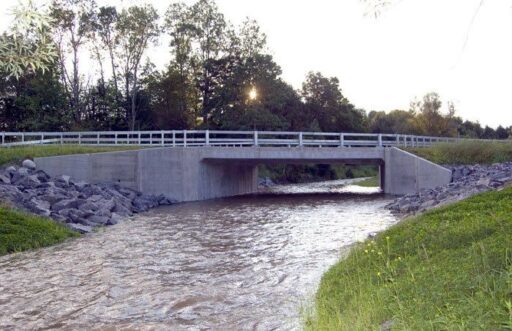

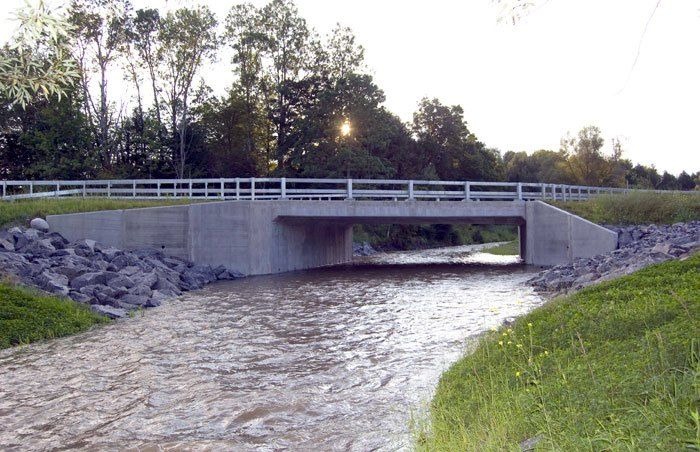

During the widening works under the National Highways Development Project (NHDP) in India, several RCC box culverts replaced older drainage systems to accommodate increased traffic intensity and heavier commercial vehicles. These structures were designed following box culvert design as per IRC guidelines, with special emphasis on verifying live load effects under IRC 70R loading.

Typical configurations included single and double-cell RCC box culverts with spans between 3 m and 6 m, constructed as permanent cross drainage structures beneath four-lane embankments. Engineers performed a detailed live load calculation example to compare IRC Class A and IRC 70R loading effects on bending moments and shear forces.

An rcc culvert example calculation conducted for selected locations revealed that shallow cushion depth led to higher negative bending moments at slab-wall junctions. The corresponding box culvert design example confirmed that live loads governed reinforcement detailing in high-traffic corridors, often more critically than dead loads.

Where embankment height exceeded 2.0 m, load dispersion improved and slab moments reduced, though lateral earth pressure on walls increased. These findings demonstrated that accurate live load evaluation directly influences slab thickness, reinforcement layout, and long-term structural performance in highway culvert projects.

Conclusion

Live loads remain a governing parameter in the safety and durability assessment of RCC box culverts, as emphasized in any comprehensive rcc box culvert design guide and aligned with culvert design standards in India. Accurate evaluation of load dispersion, soil–structure interaction, and internal force development ensures dependable structural performance under sustained traffic conditions. Codal compliance and analytical precision together form the backbone of reliable culvert engineering practice.

For professionals seeking deeper technical clarity, strengthening analytical competency through a structured structural design course and a specialized staad pro certification course supports confident handling of real-world culvert analysis and design challenges.

FAQs

1. What is live load in RCC box culvert design?

Live load refers to moving vehicular forces acting on a culvert through pavement and soil cover. As per the live load definition culvert, these loads include axle forces specified in IRC or AASHTO standards. Unlike dead load, live load varies with traffic intensity and directly affects bending moment and shear design.

2. How does cushion depth reduce live load intensity?

Cushion depth allows wheel loads to disperse before reaching the slab. This cushion depth effect reduces peak stress and bending demand on the top slab. However, increasing fill depth may raise lateral earth pressure on the walls.

3. What is IRC Class A loading?

IRC Class A loading represents standard vehicular loading defined by the Indian Roads Congress for general highways. When IRC Class A loading explained in structural terms, it simulates moderate traffic conditions with defined axle loads and spacing. It is commonly used for routine culvert design checks.

4. How is effective width calculated in culvert design?

Effective width refers to the portion of the slab that resists dispersed wheel load. The effective width calculation converts concentrated wheel loads into equivalent distributed loads based on cushion depth and geometry. This helps determine bending and shear accurately.

5. Why is FEA important for culvert analysis?

Finite Element Analysis improves accuracy in evaluating soil–structure interaction and load combinations. The FEA importance culvert studies lies in identifying stress concentration and moment redistribution. It provides more realistic results than simplified manual methods.

6. Which software is best for box culvert structural analysis?

Engineers commonly use STAAD Pro, MIDAS Civil, or SAP2000 for modeling culverts. When discussing the best software culvert analysis, STAAD Pro is widely preferred in India due to IRC load compatibility. These tools allow precise evaluation of bending, shear, and deflection behavior.