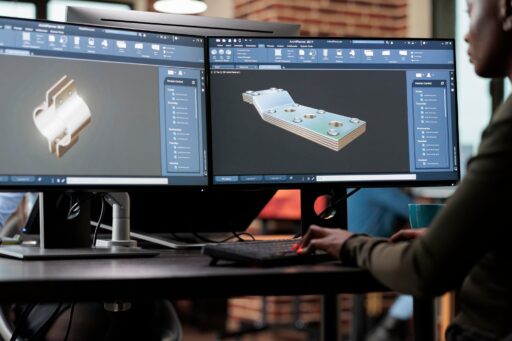

In today’s evolving engineering landscape, AutoCAD Mechanical has become a go-to tool for sheet metal design, providing a suite of powerful features that enhance productivity and precision. This blog will walk through the latest tools and features in AutoCAD Mechanical that streamline sheet metal design, offering engineers greater flexibility, efficiency, and accuracy.

Introduction to AutoCAD Mechanical for Sheet Metal Design:

AutoCAD Mechanical is designed with specialized features to support sheet metal design, an essential component in industries like automotive, aerospace, and manufacturing. Its tools are tailored to handle the intricacies of working with sheet metal, making it easier to create, modify, and analyze designs with speed and precision.

Key Tools in AutoCAD Mechanical for Sheet Metal Work:

The key to efficient sheet metal design lies in AutoCAD Mechanical’s specialized tools that cater to every phase of the design process. Some of the latest additions include:

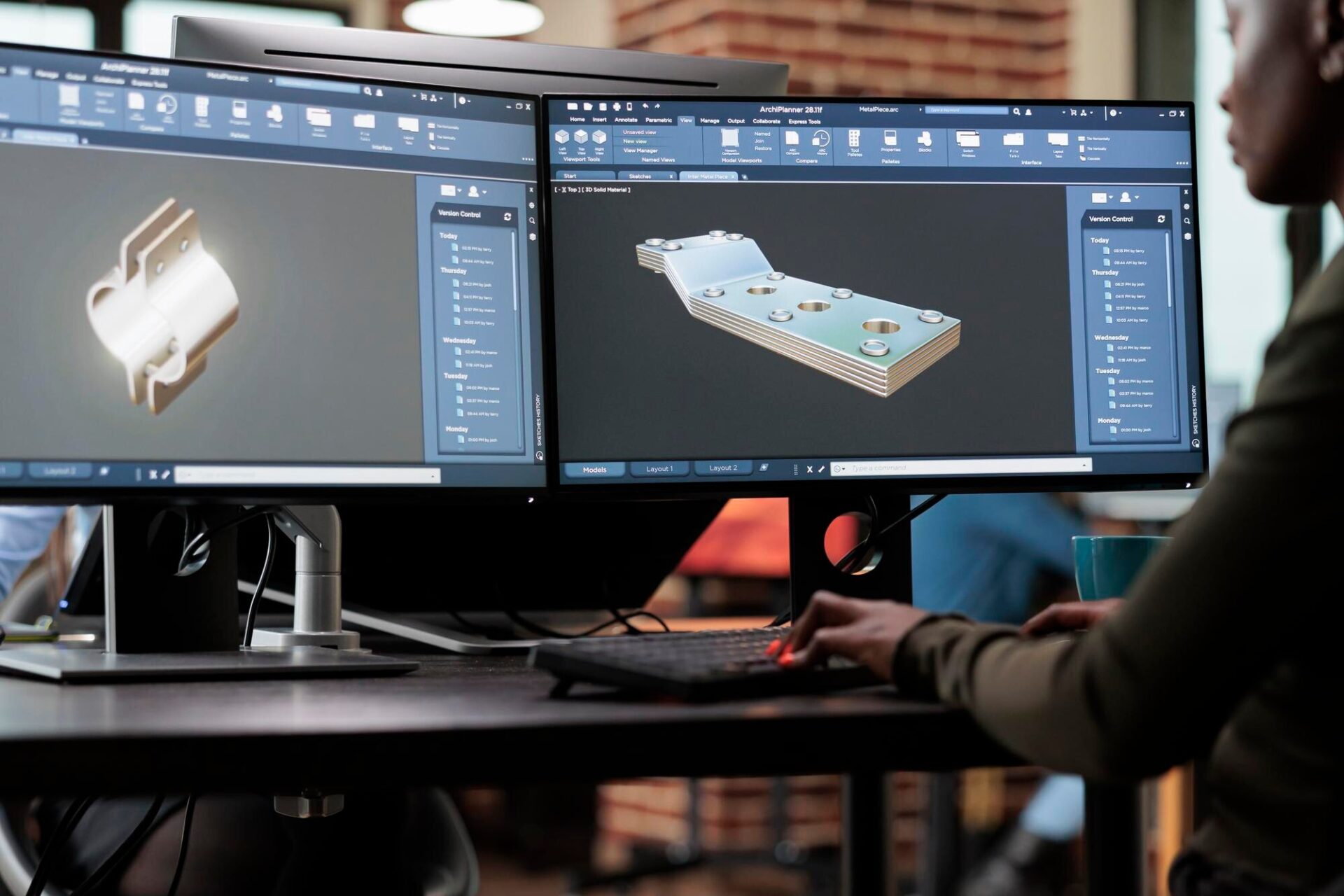

- Bend, Fold, and Flatten Tools: These tools allow for smooth transitions between 3D models and 2D representations, giving engineers full control over the bending, folding, and flattening processes.

- Standard Parts Library: AutoCAD Mechanical provides access to an extensive library of standard components like fasteners, nuts, and screws, saving time in the design phase.

- Hole Charts and BOM Generation: Easily create hole charts and bills of materials (BOM) to document sheet metal parts and assemblies more effectively.

These advanced features make AutoCAD Mechanical an essential tool for sheet metal engineers looking to optimize their workflows.

Automating Sheet Metal Design with Parametric Features:

One of the standout features of AutoCAD Mechanical is its advanced parametric design functionality, which automates repetitive tasks efficiently. With parametric design tools, engineers can establish rules and constraints for their models, ensuring that any modifications to dimensions or specifications are automatically reflected throughout the entire project. This parametric approach enhances accuracy, consistency, and reduces errors, ultimately saving significant time, especially in complex sheet metal design processes

Exploring the Sheet Metal Design Environment in AutoCAD Mechanical:

The sheet metal design environment in AutoCAD Mechanical is built to support an intuitive, streamlined workflow. Features like real-time previews and dynamic input make it easier for engineers to visualize their designs as they work. The environment also allows users to manage multiple layers, set up assembly views, and switch between 3D and 2D design spaces seamlessly.

In addition, the real-time collaboration tools enable teams to work on the same project simultaneously, increasing efficiency and reducing delays during the design process.

Sheet Metal Design Accuracy: Drafting and Annotation Tools

When working with sheet metal designs, accuracy is paramount. AutoCAD Mechanical provides a variety of drafting and annotation tools to ensure that all dimensions, tolerances, and symbols are properly represented in the design documentation. Engineers can add:

- Weld symbols

- Geometric dimensioning and tolerances (GD&T)

- Surface finish symbols

These annotation tools help improve the accuracy and readability of sheet metal design drawings, making it easier for manufacturers to interpret and execute the designs correctly.

Boosting Productivity with AutoCAD Mechanical’s Sheet Metal Features

To increase productivity, AutoCAD Mechanical offers features like automated part generation, reusable design components, and automatic layer management. Engineers no longer need to manually define every small aspect of the design, as the software intelligently manages layers, symbols, and parts. The ability to quickly generate parts and reuse them across multiple projects significantly speeds up the design process, leaving more time for engineers to focus on innovation.

Future Trends in Sheet Metal Design Using AutoCAD Mechanical:

As AutoCAD Mechanical continues to evolve, future trends in sheet metal design will likely include further integration of AI-driven tools, cloud-based collaboration, and enhanced support for advanced manufacturing techniques such as 3D printing and automated fabrication. These advancements will continue to push the boundaries of what engineers can achieve, allowing for more complex and precise sheet metal designs in less time.

Conclusion:

AutoCAD Mechanical is revolutionizing sheet metal design by providing cutting-edge tools that improve both the speed and accuracy of the design process. From parametric design and automation features to enhanced drafting tools and real-time collaboration, this software empowers engineers to deliver high-quality designs efficiently.

For those looking to master these tools and techniques, enrolling in an AutoCAD Mechanical course at CADD Centre is a great way to gain hands-on experience and professional guidance. CADD Centre offers industry-leading training, equipping learners with the skills needed to excel in sheet metal design and broader mechanical design fields. Whether you’re just starting or looking to enhance your skills, a structured course from CADD Centre can help you stay at the forefront of the latest innovations in AutoCAD Mechanical.

FAQs

What is AutoCAD Mechanical, and how is it used for sheet metal design?

AutoCAD Mechanical is a specialized version of AutoCAD that includes tools and features designed to assist engineers with mechanical design, particularly sheet metal. It helps streamline the creation, modification, and analysis of sheet metal parts, making it an essential tool in industries like automotive, aerospace, and manufacturing.

What industries benefit the most from using AutoCAD Mechanical for sheet metal design?

Industries such as automotive, aerospace, manufacturing, and industrial equipment benefit greatly from AutoCAD Mechanical’s specialized sheet metal design tools, as they allow for faster, more accurate, and efficient design processes.

What are the benefits of parametric design in AutoCAD Mechanical?

Parametric design allows you to set rules and constraints for your sheet metal designs, ensuring automatic updates when changes are made. This reduces errors and enhances consistency in complex projects.

What trends in sheet metal design should I expect with AutoCAD Mechanical?

You can expect future advancements like AI-driven tools, cloud-based collaboration, and enhanced support for 3D printing and automated fabrication in AutoCAD Mechanical.

How can I benefit from the drafting and annotation tools in AutoCAD Mechanical during the course?

CADD Centre’s AutoCAD Mechanical course will teach you to use drafting and annotation tools such as weld symbols, GD&T, and surface finish symbols. These tools will help you create accurate, detailed, and professional sheet metal designs.

How do automation features in AutoCAD Mechanical boost productivity?

Automation features such as parametric design, reusable design components, and automatic layer management help engineers save time by reducing the need for repetitive tasks. These tools enable faster part generation and ensure consistency across multiple projects.